- +91 95576 18775

- +91 85115 25161

- skengineering9557@gmail.com

What Is a Blower Fan and How Does It Work?

What Is a Blower Fan and How Does It Work?

Fans are great not only in businesses but also at home since they help in passing air and for cooling purposes. Have you ever wondered what is a blower fan and what differentiates it from a normal fan?

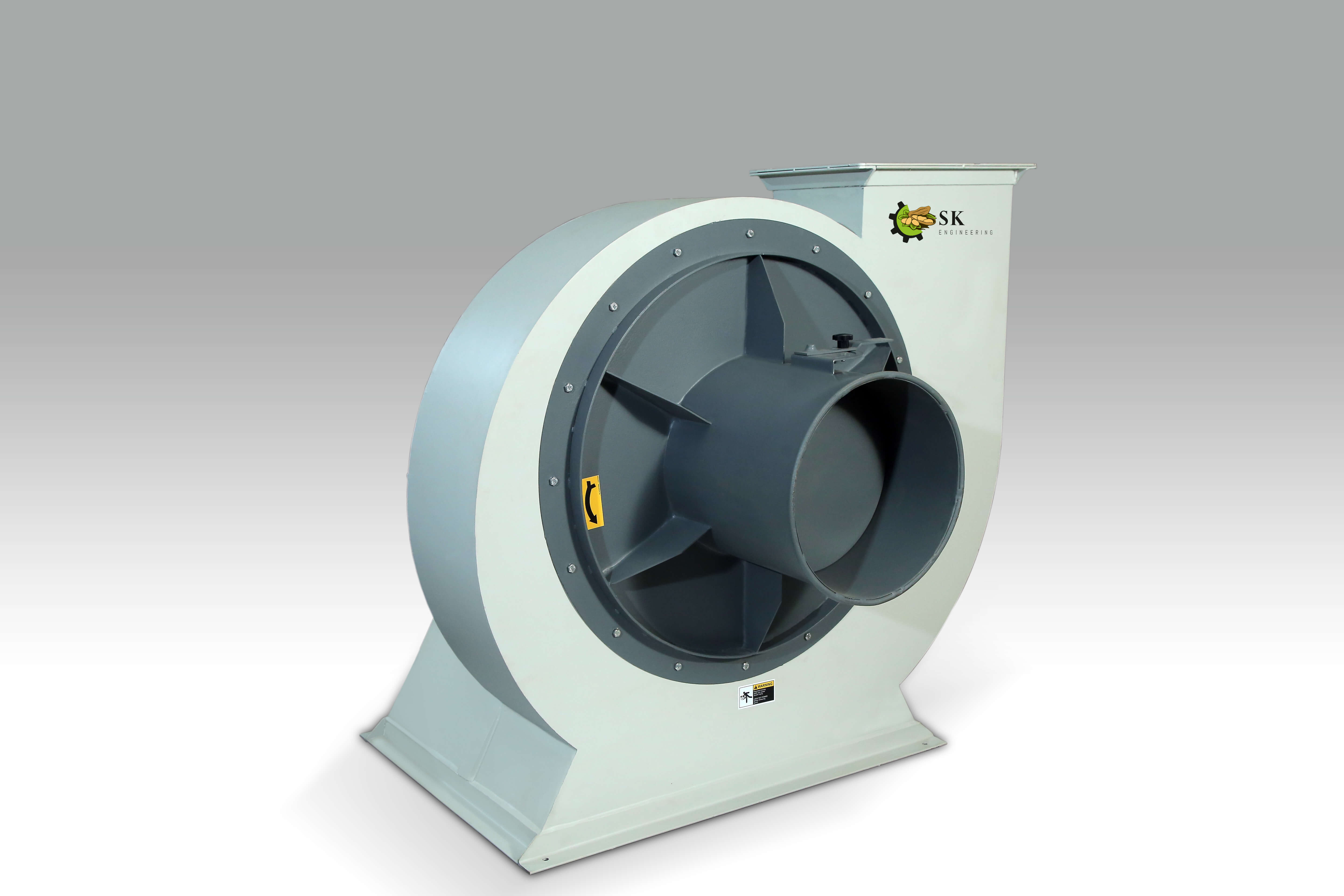

To put it simply, a blower fan is in some respect like a fan but differs in high-pressure directed streams and airflow focus. All key applications are in HVAC systems, industrial uses, electronics cooling, etc.

Here, What Is a Blower Fan, what it does, how it operates, and the classifications that would provide a better grasp of what's to be understood.

What Is a Blower Fan: An Introduction to the Concept

It's a short definition of a part of the heating, ventilation, and air conditioning (HVAC) system that is simply called a blower fan.

• The blower fan is a mechanical implement for moving air and/ or gas under pressure conditions.

• Unlike normal fans, which can move air in all directions, a blower fan has a directional air throw, usually giving rise to higher pressures than ambient air.

Thus, it may be used in situations where ventilation or suction must be greater or targeted.

In connection with environmental applications, blower fans pertain to air conditioning, heating, ventilation, and air conditioning (HVAC), electronic equipment cooling, automotive applications, and industrial applications regarding air extraction relative to dust or fumes.

What Is a Blower Fan and How Does It Function?

Of course, the way blower fans come into operation is really interesting. Here's how the blowing fan operates:

•

•

•

Now this type of high-pressure airflow is what makes a difference between blower and traditional fans; it could be centrifugal or axial, but efficient.

Types of Blower Fans: Which One Do You Need?

The investigation into blower fans requires examination of their different varieties. The select type depends on air pressure requirements in conjunction with available space and airflow direction.

1) Centrifugal Blower Fans

Blower fan operation establishes this variant as the most typical blower fan type.

• The center of centrifugal blowers pulls air entry for the fan wheel as centrifugal force distributes the air to the sides.

• These fans operate successfully under high-pressure situations, and they find use in ducted HVAC systems and factory ventilation together with equipment cooling applications.

• Centrifugal blowers provide steady airflow operation across systems that contain resistances such as ducts or filters.

Different pressure and volume requirements determine which blade design a centrifugal blower fan will use between forward-curved, backward-curved or radial styles. Their operation combines quietness with energy-saving properties.

2) Axial Blower Fans

• The rotational plane of the blades serves as an equal plane to the forward movement of air in axial blowers.

• Home air fan technology forms the basis of these devices, which boost airflow volume despite operating at reduced pressures.

• Large quantities of airflow travel easily through open areas and short pathways because of axial blower fans.

• The blower operates in car engines along with cooling towers and ventilation applications within confined areas.

3) Positive Displacement Blower:

• The industrial-grade blowers exist to deliver very precise airflow and high-pressure functions in manufacturing operations.

• The operation concept of these blowers differs from centrifugal and axial blowers, which rely on rotating blades, since they capture and transport air through their gear-based or lobe structures.

• The positive displacement blower serves applications in pneumatic conveying systems and sewage aeration, among other chemical process needs.

Key Applications of Blower Fans

Also, it entails knowing where a blower fan is employed. The uses of these fans can be found in various industries:

•

•

•

•

Specificity of high-pressure airflow directed by the blower fan is important in each of these applications.

How to Choose the Right Blower Fan for Your Needs?

•

•

•

Advantages of Using Blower Fans

A blower fan is well off many things than a fan, and they include:

• It produces focused airflow, which is ideal for applications of specific targeting.

• High-pressure output is helpful under certain industrial conditions.

• Compact design comes in small, medium, and large sizes.

• Efficient cooling and ventilation ensure safety and efficiency in machines and workplaces.

So when considering the superiority of blower fans, it should be remembered that these fans have been designed with performance and precision.

Advantages of Using Blower Fans

A blower fan is well off many things than a fan, and they include:

• It produces focused airflow, which is ideal for applications of specific targeting.

• High-pressure output is helpful under certain industrial conditions.

• Compact design comes in small, medium, and large sizes.

• Efficient cooling and ventilation ensure safety and efficiency in machines and workplaces.

Maintenance Tips for Blower Fans

For the blower fan to last for some time, maintaining it regularly is important.

•

•

•

•

Conclusion:

You must now appreciate, after expounding upon the anatomical and functional aspects of what a blower fan is, its importance in homes and industries. Some of the functions performed by a blower fan include air conditioning for buildings and protection of industrial machines from overheating.

Blower fans are different from conventional ceiling fans mainly due to their ability to discharge an air current that is unidirectional and at a pressure level that would be considered high. This unique ability makes them an asset in so many industries.

So, the next time there is a question concerning what a blower fan is, you can respond with, "It is not merely a fan, but a strong high-pressure air machine whose application is to keep systems running without a hitch."

Read More: The Future of Indian Agriculture: Multi-Commodity Processing Technology at Work